Huaswin's attention to details has become a habit

-

-

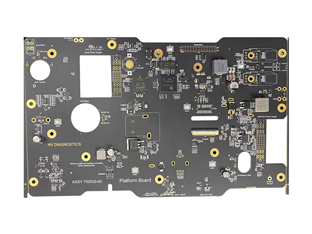

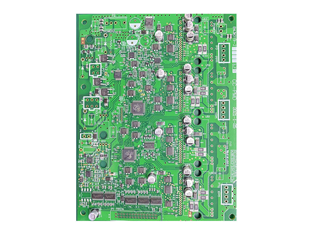

Material inspection

The quality of materials determines the service life of the PCB board. All our materials can be used in the factory only after strict inspection

-

-

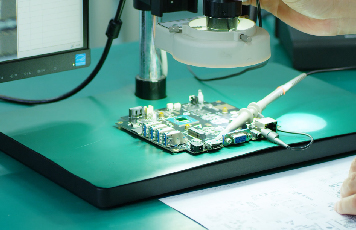

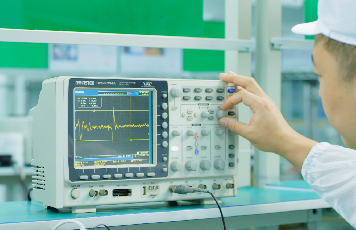

Solder paste printing test

The South Korean SPI solder paste detector is introduced to detect the height, area, volume and displacement of the tin point, so as to avoid the problems of less tin, more tin, missing printing and so on, and ensure the accuracy of solder paste printing

-

-

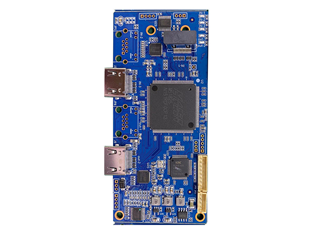

IPQC check materials

According to the engineering drawing and BOM, measure and inspect each material of the first piece board to ensure that the components pasted by the production model are consistent with the engineering drawing and BOM

-

-

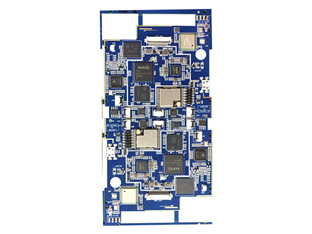

SMT first article test

According to the data of BOM and Gerber, measure and test each material of the first piece of board to ensure that the components attached to the production model fully comply with the customer's requirements and prevent defects from flowing into the next process

-

-

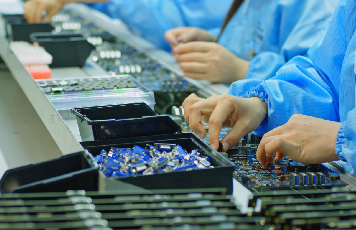

Patrol inspection of dip plug-in process

Before dip plug-ins, the key points for attention of plug-ins with direction or pin special components will be trained and explained, and quality inspectors will be arranged to conduct continuous patrol inspection during the plug-in process to ensure the quality of plug-ins

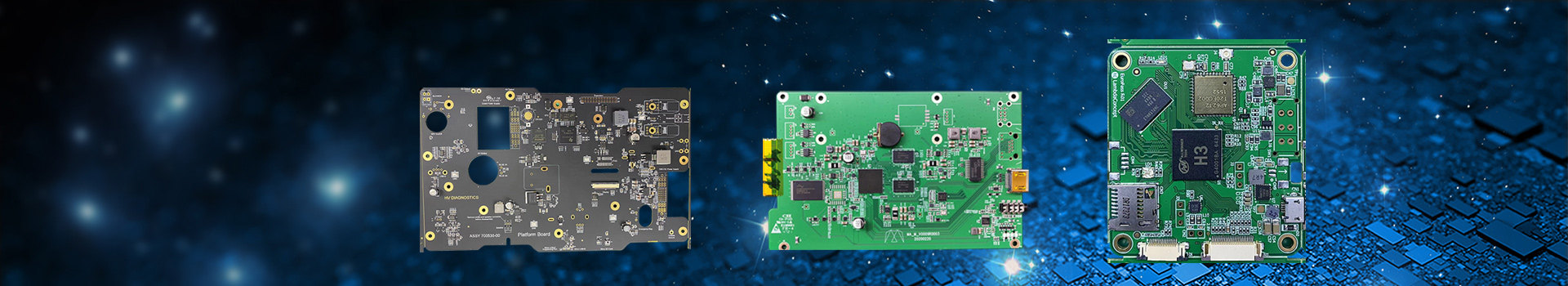

HUASWIN processing flow

- 01.Provide data quotation

- 02.Transaction order

- 03.Audit data

- 04.Component purchasing

- 05.Material counting / material preparation / IQC inspection

- 06.Baking process

- 13.X-Ray inspection

- 12.Offline AOI test

- 11.Reflow soldering

- 10.Online AOI detection

- 09.SMT patch

- 08.SPI solder paste test

Vicky

Vicky